The old saying “Win on Sunday, sell on Monday” has been around in the tire industry for decades and remains very true today. It is tangible, promotable proof of a company’s technical prowess. When a drifting fan sees a Formula DRIFT driver making incredible maneuvers on GT Radial Champiro SX2 RS tires, he or she is more likely to consider GT Radial when it comes time to purchase that next set of tires for their everyday vehicle.

You could also say “Win on Sunday, Manufacture on Monday.” Team members at the Giti plant in Richburg, SC, take great pride in their work, but there is an extra dose of pride involved when they see a GT Radial driver achieve a podium finish on tires that were developed at the Giti Technical Center in Richburg and produced in the plant.

Making a Competitive Motorsports Tire

One of the first things that you must ensure is durability, so the driver is there at the end of the race, not fuming in the pit lane. You also need power to be delivered for acceleration and speed. The more the better, and as you gain power, the need for more traction to effectively use that power to accelerate, and then the ability to better brake/decelerate the vehicle.

All race events, of course, require steering control and most require the ability for precise cornering, grip, and stability. That’s where tires come in, as they are the only part of the machine that allows the driver and the vehicle to achieve all these requirements and still be able to go, stop, and turn at the maximum (and better, faster, and longer than any of their competitors). Any failure of the tire is a limiting factor for the vehicle, the driver, and the team.

The racers also have aerodynamics applied to the vehicle to minimize drag and to add downforce, assisting in the tire grip for maximum acceleration, braking and cornering. However, this added downforce increases load and stress to the tire, creating more heat. The engineers must ensure the tire is tough enough to endure the additional stresses.

In summary, the tire engineer must be able to design the tire to:

carry the prescribed load,

control the heat,

be durable/tough and last (survive),

provide stability,

provide maximum acceleration grip/traction,

provide maximum braking/deceleration grip,

provide precise (preferably) linear steering response and feel,

provide maximum cornering grip/traction,

provide feel at the limits of adhesion/good communication at the limit/breakaway and recovery,

and, depending upon the racing environment and style of racing, deal with varying temperatures and weather/climatic conditions and varied surfaces.

Taking it to the Street

When one looks at all the requirements of the motorsports tire, you realize they are essentially the same for the street tire, especially in an emergency maneuver. At that moment in time, the tire must respond with precision and grip for cornering, as well as deceleration or acceleration to avoid an incident. The street tire needs to be durable enough, tough enough to carry the load and survive through a range of climatic, conditions and under a great deal of stress and heat to do its job.

There’s no question that racing helps develop and test materials, chemicals, component designs, engineering, shapes and contours of the tire, reinforcement materials, positions, tread compounds, tread shapes, footprint, and tread designs – all tailored to maximize a facet of the handling and performance package, whether grip, control, durability, or forgiveness.

In effect, every race is a test session for the engineers and designers who are constantly pushing the boundaries to provide their drivers that advantage over their competitors.

Look at the history of Indy, NASCAR, Formula 1/Formula Car racing, European Rallye, Le Mans, 24 Hours of Nürburgring, Hill Climbs (Pikes Peak), drag racing, sports car racing (road racing/circuit racing), Score racing, and today’s drifting. From each of these we can find improvements in tire design, tire material, compounding and tread design that have helped win races and later translated into better performing street tires.

Not everything will directly convert to a street application, as race tires are designed for a much shorter time period and particular type of racing. The tires are “tuned” specifically for a particular race series, and in some cases, a specific event. Some racing series may need to have a heavier tire, others a lighter one. Some are tuned for banked corners, while others are designed for flat and even off-camber corners

Winner Produced in Richburg

In the development of the GT Radial Champiro SX2 RS, it is not difficult to find a direct correlation between motorsports and the street because this tire was developed for both Formula DRIFT competition and enjoying a fun drive on California Highway 101.

After a few years of drifting involvement using the GT Radial Champiro SX2 ultra-high performance street tire, the drivers came to Giti asking for a tire designed for the real essence of Formula DRIFT. To begin the development work, the engineers interviewed drivers about their key priorities. The drivers wanted a “toss-able” tire with great “feel,” progressive breakaway behavior and recovery, along with tremendous grip to gain forward thrust and accelerate off the corners.

Formula DRIFT drivers start their run and accelerate to high speeds, then “toss” the car sideways at these high speeds headed into a chicane, then a walled corner and glide through the corner sideways within inches of the concrete wall in a “dance” with their competitor. They then need to “hook-up” better and pull away off the corner. Oh, and this tire needs to create lots of smoke and yet survive the extreme temperatures far above what a normal street tire and even most race tires will ever see!

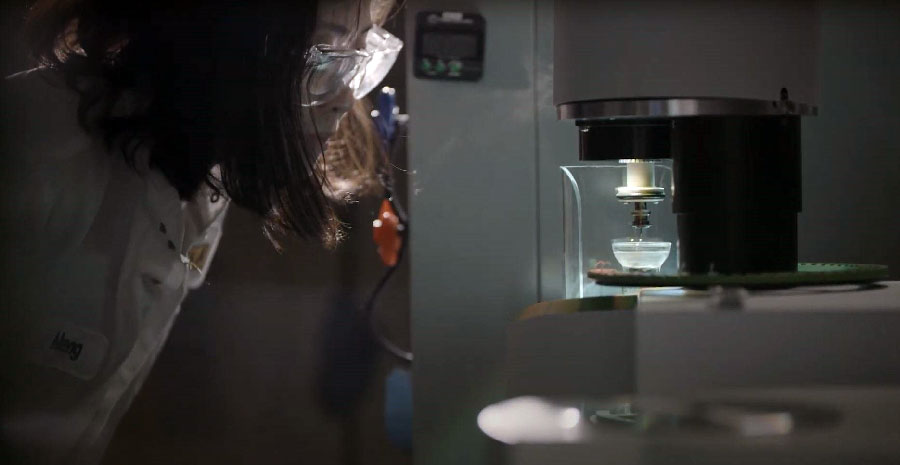

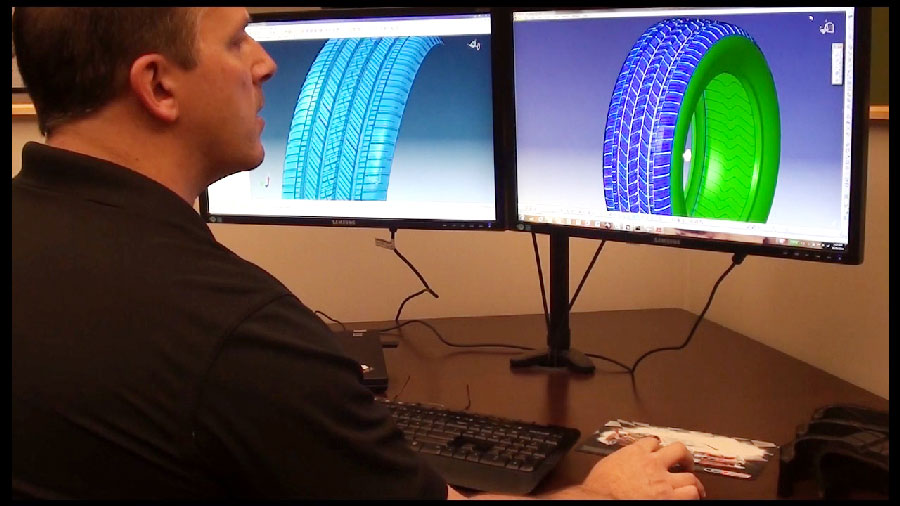

The engineers at the Giti Technical Center in Richburg, SC, in conjunction with Giti’s global R&D centers, dove into the task looking at the tire structure, carcass shape, materials (components) and compounds. In its first year in Formula DRIFT competition, the Champiro SX2 RS, developed and manufactured in South Carolina, assisted in multiple podium finishes; six of the top 12 competitors in the final driver points standings were GT Radial drivers.

The same attributes that make the Champiro SX2 RS a highly competitive drifting tire – durability, tremendous grip and predictable handling – also make it a desirable option as a street tire for the true performance enthusiast.

Phang Wai Yeen, CEO Giti Tire Manufacturing and former Director of Giti Motorsports R&D, explains race tire development this way: “It all begins with understanding the mindset of the driver. That’s the job of the vehicle dynamics engineer, who’s trained as a test driver, as well as in tire engineering. He works with the construction engineer to design the construction of the tire that will be able to take the required forces. Two things matter. The first is maximizing the contact patch. No matter how powerful the car – handling to traction to cornering forces to braking – it all depends on the interaction between the tread surface and the road. At the end of the day, those four patches have to work.”

Secondly, Phang notes, “The tire casing has a lot to do with the stability of the contact patch footprint, helping to dictate how the tire reacts and stabilizes itself against the dynamic forces generated by the car. If the car is being bounced all over the road and pushed into the corners, the casing has to behave in such a way to allow the footprint to work.”

In normal road car tire development, road cars may never be taken to the limits of the tires designed for that vehicle. In motorsports the tires are always being pushed to the limits, and solutions are always needed “yesterday.” This becomes a stimulus to hasten tire development. It leads to better and safer tires for the driving public.